| Print Control | ||

| PH Technology | High-precision piezoelectric printhead | |

| Print Resolution | Maximum resolution up to 1200x600dpi | |

| Productivity | 1200x600dpi:60m/min | |

| Inks | ||

| Ink type | UV ink | |

| Color option | CMYK+W+O/V | |

| Ink Tank Capacity | 5 L/C、3L/W | |

| Media Handle | ||

| Media Feeding | Tension detection, paper break detection, roll diameter detection, etc. | |

| Tension control | Full closed-loop tension control system | |

| Max. Roll Diameter | Max. roll diameter:1000mm, core:76mm 3'' air shaft | |

| Media Thickness | 0.04-0.35mm | |

| Media Type | Coated paper, synthetic paper and film, PE/PET/PVC, etc. | |

| Max. Print Width | 350mm | |

| Corona System | Contact double-sided dust removal device | |

| Anti-static System | In and out inkjet system plasma static elimination | |

| Max. Media Width | 350mm | |

| Wind System | Including press system | |

| RIP Data Interface/RIP | ||

| Data Interface | Fiber optic transmission | |

| Operation Interface | Visual simple UI interface | |

| Dimension/Weight | ||

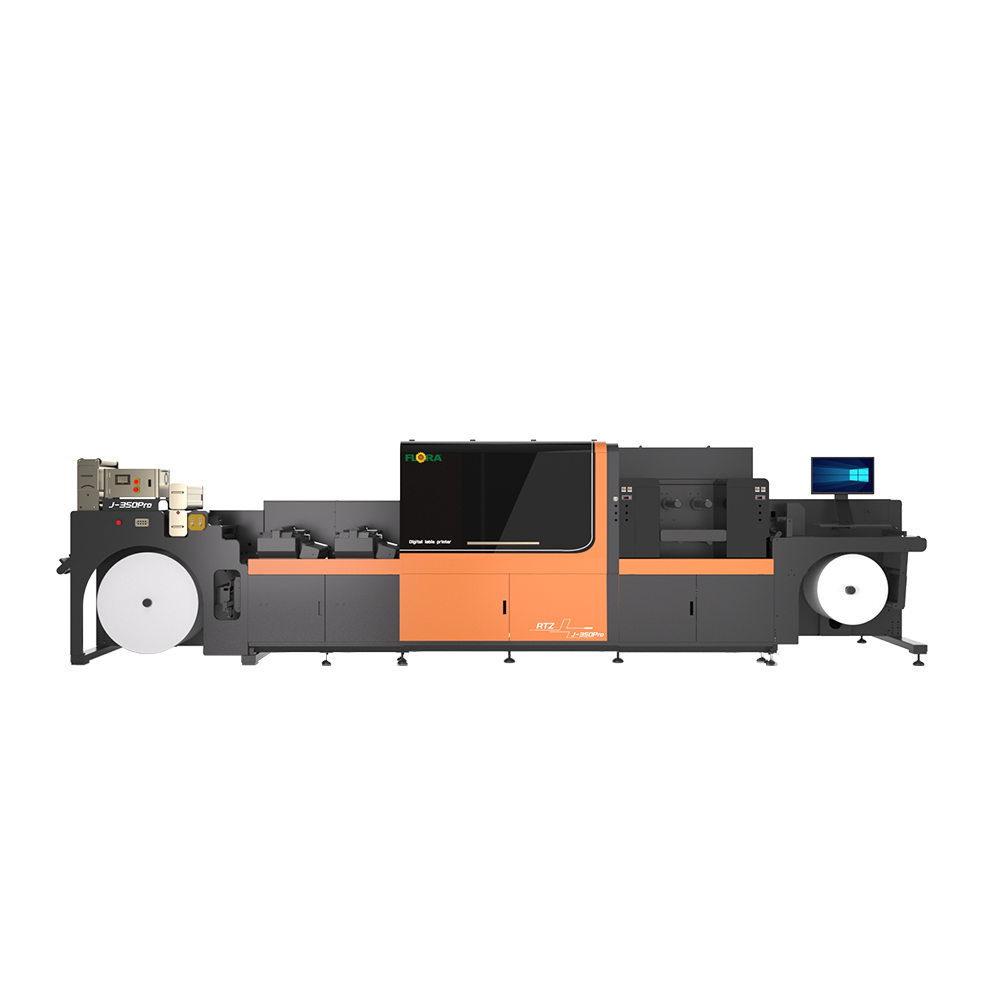

| LxWxH | 7000x2040x2100mm | |

| Weight | 5500kg | |

| Set-up Space | ≈14㎡ | |

| Optional | ||

| Coating unit | size 330mm, 200 teeth, printable | |

| Cold ironing unit | Including cold ironing, winding and unwinding unit | |

| Glazing unit | size 330mm, 200 teeth, printable | |

| Still picture | BST | |

| Laminated unit | Cold perm and roll up in the same style, including a covered bracket | |

| Installation Condition | ||

| Condition | 20-25℃,30-70% (non condensation) | |

| Best condition | 22.5-27.5℃,45-65% (non condensation) | |

| Power supply | 380VAC,3L+N+PE,50-60Hz;Max. 55kw | |

| Compress air | 0.6MPa, clean without condensation | |

| Warranty | One year (Please (onsult your local deler for details)) | |

|

*the final specification of the machine is subject to actual product. Please contact the sales manager for the latest specification data. *The company reserves the right of final interpretation of this brochure. |

||

-Wide colour gamut, expandable

CMYK configuration for accurate colour reproduction, covering around 85% of the Pantone colour gamut Support for spot colours and varnishes Dual white channels with front and back white support for printing on transparent materials with both back and cover whites

-Automatic cleaning and moisturising

One-key automatic cleaning function, saves a lot of startup time and maintenance time Automatic moisturisation on standby to effectively protect the nozzles and prevent plugging

-High accuracy and speed

High precision: grey scale printing, minimum ink droplet 3pl, maximum print resolution 1200x600dpi 60m/min

-Auto unwind/wind system

Quick and easy reel change, automatic reel lift, great labour saving Material reversal kinetic energy, which can significantly reduce material waste

-Highly integrated software operating platform

Suspended hand touch screen, highly integrated software User-friendly interface, easy to understand and quick to use Real-time statistics on completed orders, print area and ink consumption, making it easy for customers to manage jobs and costs Hole compensation technology to reduce the degradation of print quality caused by skewed or non-sprayed holes Full colour variable data printing, supporting variable data printing such as 2D codes and barcodes Software configuration: variable data optional Hardware configuration: foil stamping, laminating, varnishing, still picture, coating, etc.