| Print Control | ||

| PH Technology | High-precision piezoelectric printhead | |

| Print Resolution | Maximum resolution up to 1200x1200dpi | |

| Productivity | 75m/min | |

| Inks | ||

| Ink type | UV ink | |

| Color option | CMYK+W | |

| Ink Tank Capacity | 5 L/C、3L/W | |

| Media Handle | ||

| Media Feeding | Tension detection, paper break detection, roll diameter detection, etc. | |

| Tension control | Full closed-loop tension control system | |

| Max. Roll Diameter | Max. roll diameter:1000mm, core:76mm 3'' air shaft | |

| Media Thickness | 0.04-0.35mm | |

| Media Type | Coated paper, synthetic paper and film, PE/PET/PVC, etc. | |

| Max. Print Width | 350mm | |

| Corona System | Contact double-sided dust removal device | |

| Anti-static System | In and out inkjet system plasma static elimination | |

| Max. Media Width | 370mm | |

| Wind System | Including press system | |

| RIP Data Interface/RIP | ||

| Data Interface | Fiber optic transmission | |

| Operation Interface | Visual simple UI interface | |

| Dimension/Weight | ||

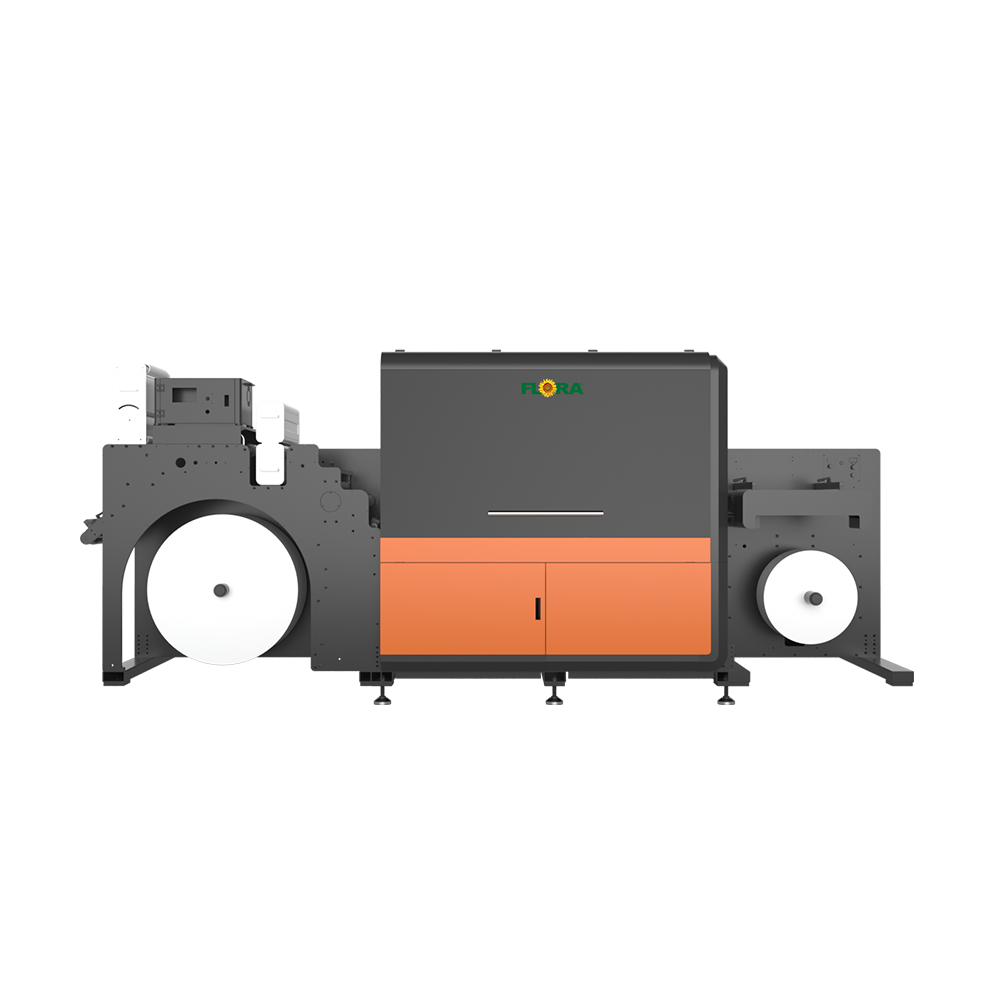

| LxWxH | 4360x1860x1900mm | |

| Weight | 3500kg | |

| Set-up Space | ≈8.15㎡ | |

| Optional | ||

| Film covering | With adhesive film | |

| Still picture | BST | |

| Installation Condition | ||

| Condition | 20-25℃,30-70% (non condensation) | |

| Best condition | 22.5-27.5℃,45-65% (non condensation) | |

| Power supply | 380VAC,3L+N+PE,50-60Hz;Max. 55kw | |

| Compress air | 0.6MPa, clean without condensation | |

| Warranty | One year (Please (onsult your local deler for details)) | |

|

*the final specification of the machine is subject to actual product. Please contact the sales manager for the latest specification data. *The company reserves the right of final interpretation of this brochure. |

||

-Wide colour gamut, expandable

CMYK configuration for accurate colour reproduction, covering around 85% of the Pantone colour gamut

-Automatic cleaning and moisturising

One-key automatic cleaning function, saves a lot of startup time and maintenance time Automatic moisturisation on standby to effectively protect the nozzles and prevent plugging

-High accuracy and speed

High precision: grey scale printing, minimum ink droplet 3pl, maximum print resolution 1200x1200dpi 75m/min

-Auto unwind/wind system

Quick and easy reel change, automatic reel lift, great labour saving Material reversal kinetic energy, which can significantly reduce material waste

-Highly integrated software operating platform

Suspended hand touch screen, highly integrated software User-friendly interface, easy to understand and quick to use Real-time statistics on completed orders, print area and ink consumption, making it easy for customers to manage jobs and costs

-Others

Hole compensation technology to reduce the degradation of print quality caused by skewed or non-sprayed holes Full colour variable data printing, supporting variable data printing such as 2D codes and barcodes Software configuration: variable data optional Hardware configuration: foil stamping, laminating, varnishing, still picture, coating, etc.