| Printing technology | |

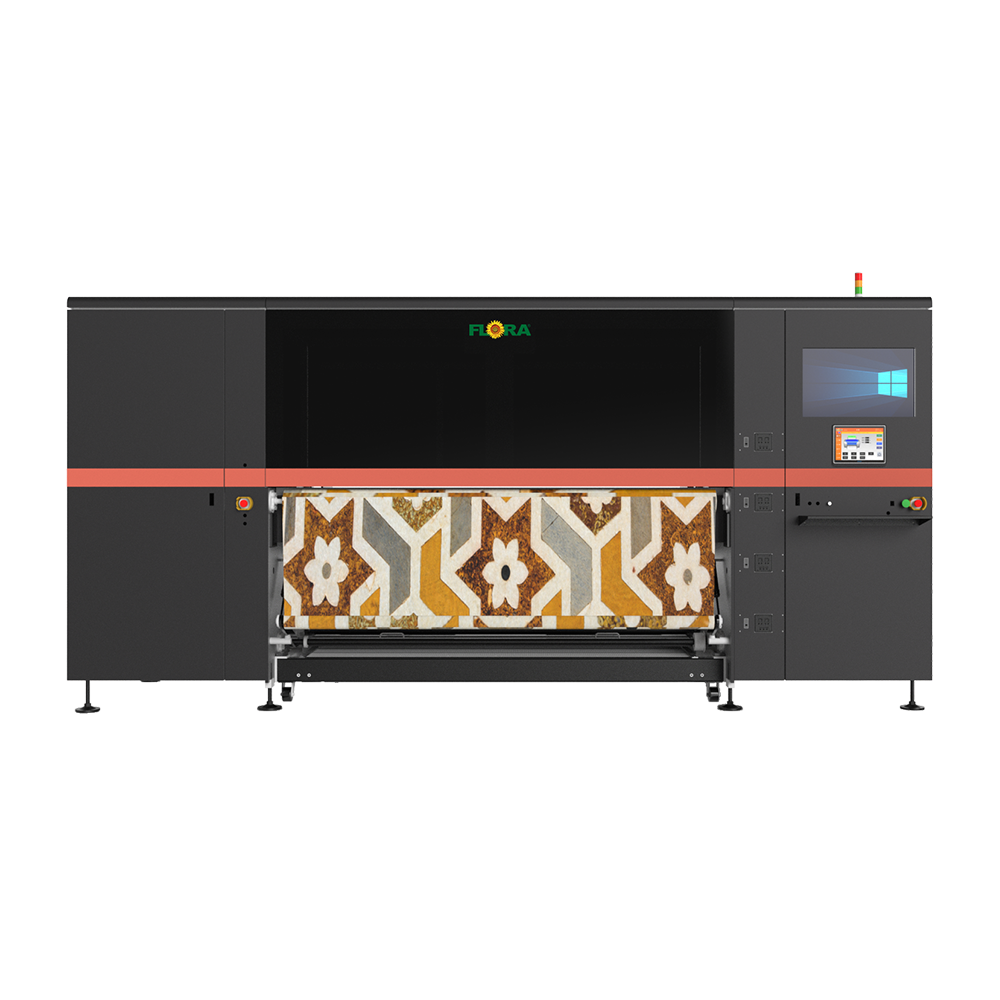

| Printhead | EPSON S3200-A1,24 |

| Printing speed | Express Mode 1300M²/h |

| Quanlity Mode 650M²/h | |

| Printhead maintain | Automatic cleaning and moisturizing |

| Ink solution | |

| Ink type | Dye sublimation ink, Pigment ink |

| Color scheme | 6 colors |

| Cartridge capacity | 10L/color |

| Ink supply mode | Automatic degassing, automatic negative pressure, ink circulation |

| Media handling system | |

| Media loading | roll to roll |

| Media dimension | Max. roll diameter 1100mm, Max.weight 1000KG |

| Printing format | Max. 2000mm |

| Media format | Max. 2050mm |

| Media type | Heat transfer paper, wood grain paper, corrugated paper, film, etc. the minimum weight of 31g |

| Data transfer | |

| Data interface | Optical data communication,USB3.0 |

| Rip software | FLORA ,NeoStampa,ONYX,other |

| Dimensions | |

| Machine size | Net size (LxWxH) : 4300 x 1400 x 2300mm Package size (LxWxH) : 4450 x 1400x 2350mm |

| Rewinding size |

Net size (LxWxH) : 2610 x1300 x 1150mm Package size (LxWxH) : 2700 x 1550 x1450mm |

| Net weight | Machine is 2300KG, Winding is 500KG |

| Environment requirements | |

| Temperature | 25~28℃ |

| Humidity | 60%~70% no-condensing |

| Power & Air pressure requirements | |

| Power |

Machine:AC380V±10% 50/60HZ 20A Dryer:AC380V±10% 50/60HZ 63A |

| Air | Clean and dry air ≥0.6Mpa, 0.6M3/min, Air tank≥30L |

| Warranty | |

| 12 months(Please contact local distributors for more information.) | |

-Media transmission

Constant tension control technology to make precise step. Make sure the printing has no contact marks and no misplace at both direction.

-Production efficiency

Multi-printheads splicing technology, can run single pass with a amazing scan width. Production efficiency doubled and let customers reduce purchase cost..

-Rewind and unwind system

Unwind system support 10000m material, rewind system support 1000m material. Low material loss, effectively reduce the material cost.

-Material drier

Automatic constant-temperature drying system. Adjust according to demand, more energy efficient.

-Auto clean

Printhead automatic wipe cleaning system. Maintenance is simple , improving production speed effectively.

-Circulation

Ink circulation system. Printing is more stable and smooth.

-Intelligent control

PLC and touch panel interface to enable a more stable, convenient and humanized system.