| Print Technology | ||

| Print head | Industrial on-demand inkjet piezo printhead S3200 series | |

| Resolution | Max 1200×600dpi | |

| Productivity | 450 x 600dpi:90m/min | |

| 600 x 600dpi:60m/min | ||

| 900 x 600dpi:45m/min | ||

| 1200x600dpi:30m/min | ||

| Inks | ||

| Ink type | AQ ink | |

| Color Option | CMYK | |

| Ink Tank Capacity | 5L/C | |

| Media Handle | ||

| Material transfer | Professional fore-edge feeding system, strong vacuum table | |

| Feeding width |

Min. feed width 500mm Max. feed width 2500mm |

|

| Print width |

Standard print width 805mm Max print width 1610mm |

|

| Feeding length |

Min. feed length 400mm Standard maximum feed length 1500mm (plus rear tray supports up to 4000mm) |

|

| Media thickness | 1.5-15mm | |

| RIP/ Data Interface | ||

| Data Interface | USB 3.0 | |

| RIP software | Onyx, open for the third part RIP | |

| Dimension & Weight | ||

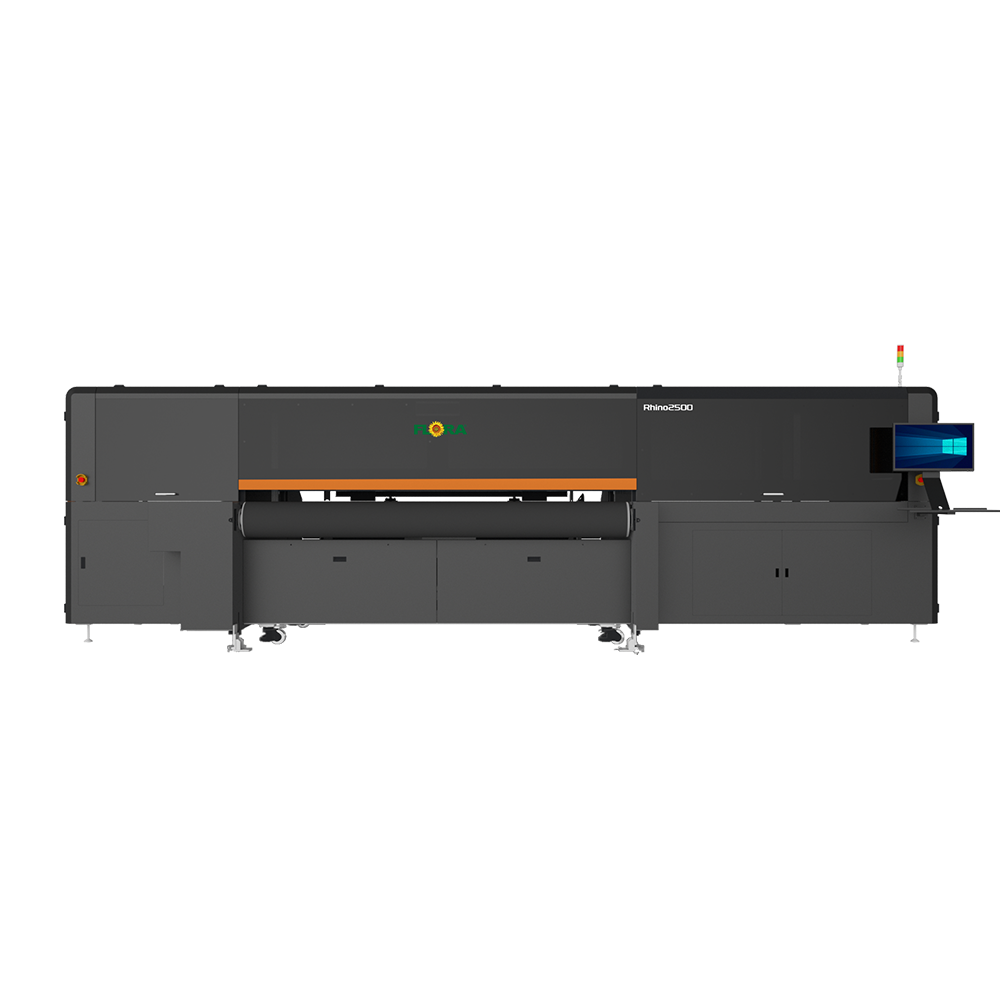

| Machine | 6200 × 3710 × 1820mm,5500kg | |

| Printing Unit | 6400 × 2180 × 2240mm,4000kg | |

| Feeder | 4500 × 1450 × 2140mm,2800kg | |

| Operation Condition | ||

| Environment | Low dust, less light | |

| Temperature | 20-35℃,(ideal condition) | |

| Relative humidity | 50%~70%(ideal condition) | |

| Installation Requirements | ||

| Power supply | AC380-400V,3 Phase,40A,50/60Hz,20kW | |

| Compress air | Dry compressed air,6-8 bar | |

| Warranty | ||

| One year (Please consult your local deler for details) | ||

|

*the final specification of the machine is subject to actual product. Please contact the sales manager for the latest specification data. *The company reserves the right of final interpretation of this brochure. |

||

-Three rows of print heads, multiple configuration

- Standard CMYK, satisfy most of customer's request

- Support online upgrade, configuration upgrade from economy version to high-speed version

-Automatic cleaning & moisturizing system

- Automatic cleaning system, simple and convenient maintenance

- Automatic moisturizing system, greatly reduce the maintenance times of print head,improve production efficiency

-Industrial belt conveyor, vacuum adsorption

Industrial belt conveyor, strong vacuum suction, greatly ensure the smoothness of the sbustrates Ensure paper feeding accuracy to feed evenly

-Auto-stacker system(optional)

Automatic stacker system

Max. media size up to 2500×1350mm

-Friendly GUI, easy operation

PLC real-time displays the printer status The friendly GUI is easy to learn and operate, able to calculate the ink volume for each printing job

-Auto-feeder

Automatic feeding system, save labor, increase productivity

Max. media size up to 2500×1500mm